Push-Pull are designed for palletless packed goods handling and stacking operations. With the aid of slipsheet which replaces pallet, sheets with loads on were pulled onto the carrying plate of set and were pushed out to spot of destination. It features of high productivity with easy maintenance and lower running cost are gained. And mainly used industries such in petrochemical, chemical, pharmaceutical, logistic industries and any other industries that uses palletless handling systems.

Functions & Applications

Pusher/Push Pull is designed for slipsheet applications requiring high productivity with easy maintenance.

Features

● Excellent driver visibility

● Flexible spacing between both fork planks

● Smooth contact parts ease the damage of slide plate

● Strength and durability to work in demanding applications

● High strength and secure structure

● Simplified hydraulic system

● Smooth operation with the buffering function of cylinder

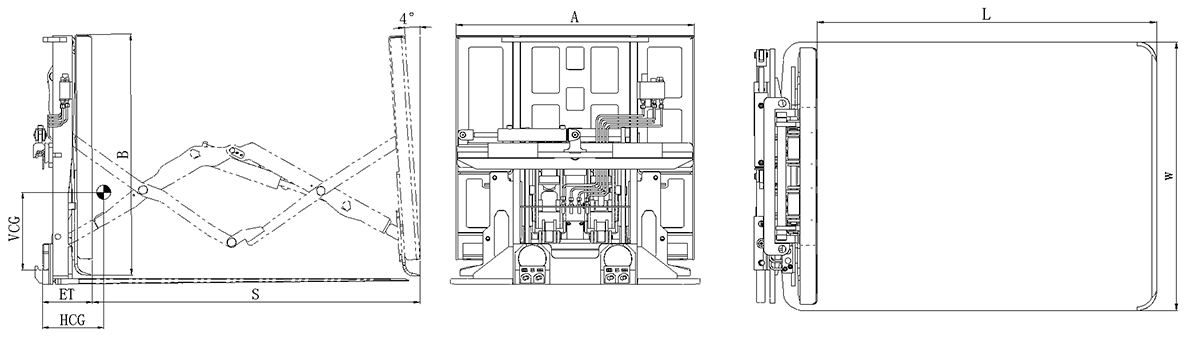

| Capaticy@ Load Center | Catalog Order No. | Platen Size | Carrying Plate size | Mounting Class | Stroke | Vertical Center of Gravity | Weight | Effective Thickness | Horizontal Center of Gravity |

| (kg@mm) | (mm) | (mm) | VCG(mm) | (kg) | ET(mm) | HCG(mm) | |||

| 2000@600 | TLQ20D-B016 | 1150x1065 | 1300x1100 | II | 1350 | 250 | 564 | 230 | 354 |

| 2000@600 | TLQ20D-C006 | 1050x1065 | 1400x1100 | III | 1440 | 255 | 572 | 230 | 369 |

| 2000@600 | TLQ20D-C008 | 1050x982 | 1220x1050 | III | 1270 | 251 | 525 | 230 | 326 |

Recommend Hydraulic Flow: 40L/min –120L/min

Pressure: 160 Bar

Note

1. Please contact FLT manufacture for the residual capacity of attachment

2. 1 additional hydraulic circuit required

Also available with sideshifting, 2 additional hydraulic circuits

* Further technical details are available upon request