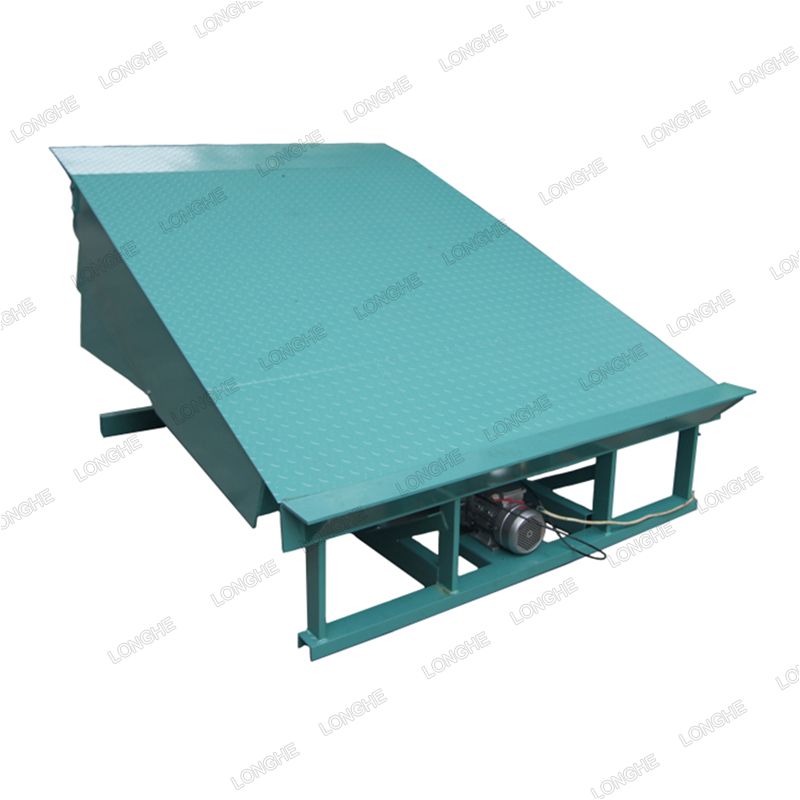

What are Dock Levelers?

Dock levelers are devices used to bridge the gap between a warehouse dock and a trailer. They ensure the safe and efficient transfer of goods, accommodating for height differences between the dock and the vehicle.

Types of Dock Levelers

Mechanical Dock Levelers

How They Work

Hydraulic dock levelers are push-button activated. They utilize fully powered raise and lip extension functions with hydraulic cylinders and individual or multi-unit hydraulic pump and motor stations. Mechanical dock levelers are the easiest to operate and lowest maintenance available. Hydraulic dock levelers operate through a system of springs and levers. When a dock worker pulls a chain, the springs release, lifting the deck of the leveler to the height of the trailer.

Key Features

- Manual Operation: Requires physical effort to engage and disengage.

- Springs and Levers: The primary mechanism involves springs, which need regular adjustment.

- Cost-Effective: Generally lower initial cost compared to hydraulic systems.

Hydraulic Dock Levelers

How They Work

Hydraulic dock levelers use an electric pump to power hydraulic cylinders, which raise and lower the deck. This process is controlled with the push of a button, making it more user-friendly.

Key Features

- Automatic Operation: Minimal physical effort required.

- Hydraulic System: Provides smooth and precise operation.

- Higher Initial Cost: More expensive upfront but offers additional features and benefits.

Mechanical vs. Hydraulic Dock Levelers

Comparison Overview

While both mechanical and hydraulic dock levelers aim to achieve the same goal, they do so through different mechanisms. Here’s a closer look at how they compare in various aspects.

Installation Process

Mechanical Dock Levelers: Installing mechanical dock levelers is relatively straightforward. It involves mounting the leveler to the dock and ensuring the springs and levers are correctly set up.

Hydraulic Dock Levelers: Hydraulic dock levelers require a more complex installation process due to the hydraulic system and electrical components. Professional installation is often recommended.

Maintenance Requirements

Mechanical Dock Levelers

- Regular Adjustments: Springs and levers need frequent adjustments.

- Lubrication: Moving parts require regular lubrication to prevent wear.

Hydraulic Dock Levelers

- Minimal Maintenance: Hydraulic systems generally require less maintenance.

- Annual Inspections: Regular inspections are recommended to ensure the system is functioning correctly.

Cost Considerations

Initial Cost

- Mechanical Dock Levelers: Generally lower initial cost.

- Hydraulic Dock Levelers: Higher upfront cost due to the advanced system.

Long-term Cost

- Mechanical Dock Levelers: Potentially higher maintenance costs over time.

- Hydraulic Dock Levelers: Lower maintenance costs, which can offset the initial investment.

Safety Features

Mechanical Dock Levelers

- Manual Safety Mechanisms: Includes safety legs and lip extensions.

- Risk of Injury: Higher risk due to manual operation.

Hydraulic Dock Levelers

- Automatic Safety Features: Includes hydraulic velocity fuse and emergency stop.

- Safer Operation: Reduced risk of injury due to automated controls.

Durability and Lifespan

Mechanical Dock Levelers

- Durability: Can be very durable if maintained properly.

- Lifespan: Typically shorter due to wear and tear on mechanical parts.

Hydraulic Dock Levelers

- Durability: High durability with less wear and tear.

- Lifespan: Longer lifespan due to robust construction and minimal manual intervention.

Operational Efficiency

Mechanical Dock Levelers

- Time-Consuming: Manual operation can be time-consuming.

- Consistency: Performance can vary based on operator efficiency.

Hydraulic Dock Levelers

- Quick Operation: Push-button controls ensure quick and consistent operation.

- Efficiency: Generally more efficient and consistent in performance.

Suitability for Different Environments

Industrial Settings

- Mechanical Dock Levelers: Suitable for environments with low to moderate traffic.

- Hydraulic Dock Levelers: Ideal for high-traffic industrial environments requiring frequent loading and unloading.

Commercial Settings

- Mechanical Dock Levelers: Adequate for small to medium-sized businesses.

- Hydraulic Dock Levelers: Preferred for large-scale commercial operations.

Pros and Cons

Mechanical Dock Levelers

Pros:

- Lower initial cost

- Simple installation

- Effective for less frequent use

Cons:

- Higher maintenance

- Manual operation can be strenuous

- Shorter lifespan

Hydraulic Dock Levelers

Pros:

- Easy to operate

- Low maintenance

- Long lifespan

- Safer and more efficient

Cons:

- Higher initial cost

- Complex installation

Conclusion

Choosing between mechanical and hydraulic dock levelers depends on your specific needs, budget, and operational environment. Mechanical dock levelers are cost-effective and suitable for less demanding applications, while hydraulic dock levelers offer superior performance, safety, and efficiency for high-traffic environments. Assessing these factors will help you make an informed decision that best suits your requirements.

FAQs

1. What is the main advantage of hydraulic dock levelers over mechanical ones?

- Hydraulic dock levelers are easier to operate and require less maintenance compared to mechanical dock levelers.

2. Are hydraulic dock levelers more expensive to maintain?

- No, hydraulic dock levelers generally have lower maintenance costs compared to mechanical dock levelers.

3. Can mechanical dock levelers handle heavy loads?

- Yes, but they may require more frequent maintenance and adjustments to handle heavy loads effectively.

4. What safety features do hydraulic dock levelers offer?

- Hydraulic dock levelers typically include automatic safety features like hydraulic velocity fuses and emergency stop buttons.

5. Which type of dock leveler is more suitable for a high-traffic environment?

- Hydraulic dock levelers are more suitable for high-traffic environments due to their efficiency and ease of use.