If you own a business that relies on forklifts daily, you’re likely familiar with their operation. However, if you need to handle specific materials like hay, paper rolls, or similar items, a forklift clamp attachment can significantly enhance your efficiency and ease of use. A forklift clamp is an ideal solution for moving a variety of materials across different industries.

What Are Forklift Clamps?

Forklift clamps are attachments that enable operators to safely handle uniquely shaped products, from round loads to cartons. A forklift clamp is an attachment that’s fastened to the mast of a forklift. These clamps are usually put in the place of a traditional fork attachment.

There are several types of forklift clamps available for you to choose from, and each one is designed to handle specific materials with care. The type of clamp you need will depend on your business requirements, and it’s essential to consider the clamp’s capacity in relation to the forklift's capacity and the weight of the products. Additionally, the weight of the clamp will impact your forklift’s overall weight limits.

Different Types of Forklift Clamp Attachments

There are various forklift clamp options tailored for different materials and purposes. The most common types used by businesses include:

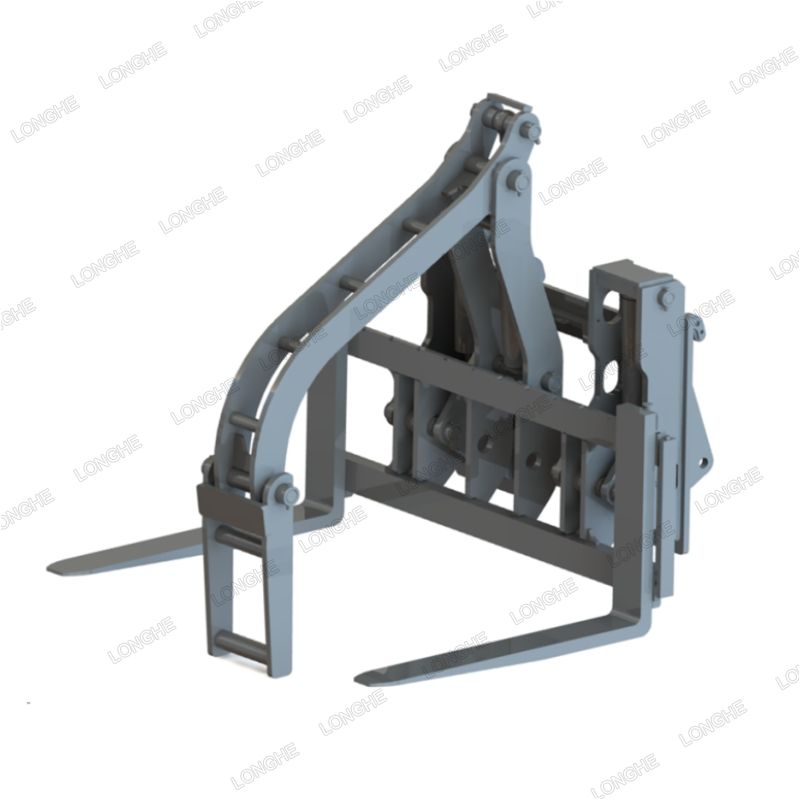

- Fork Clamps: Designed for awkwardly shaped loads like tires, fork clamps facilitate safer and easier handling of materials that are typically challenging to manage.

- Bale Clamps: Ideal for handling materials that don’t use pallets, such as hay, cotton, or wool, bale clamps are versatile attachments.

- Appliance/Carton Clamps: These clamps are often used to safely handle packaged shipments of vegetables, wine, and other palletless materials.

- Paper Roll Clamps: Perfect for transporting paper rolls, these clamps feature a smooth design that prevents rolls from falling during transport.

- Concrete Block Clamps: Specifically designed to securely transport concrete blocks or bricks, these clamps have softer elements for cushioning, protecting the products from damage.

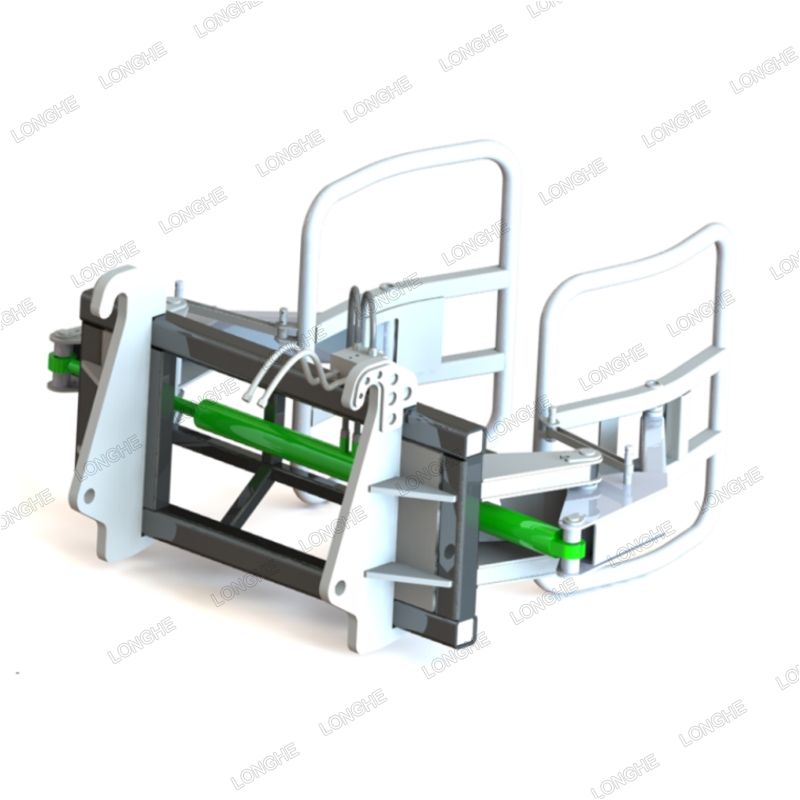

- White Goods Clamps: Suitable for a wide range of boxed appliances, these clamps use articulating pads and a stabilizer design to minimize product damage by requiring less force to support a load.

- Forward Rotating Arm Clamps: Designed for T-loading refrigerators, these clamps operate in three simple steps: clamp and rotate, unclamp, and reclamp before driving into the trailer.

- Appliance Clamp with Forks: Also known as the "shopping clamp," this type is ideal for pallets that only need occasional movement, allowing for efficient loading as you navigate the warehouse.

Before purchasing a forklift clamp, it’s important to determine which type will best suit your business needs. Consulting with a professional can help you select the right clamp before finalizing your purchase.

Benefits of Using Forklift Clamps

Forklift clamps are essential for handling non-palletized products, allowing operators to manage these items carefully without causing damage. Their efficient designs and the use of soft materials, such as cushioning, enhance productivity and safety on the job site. By keeping products in optimal condition during transport, forklift clamps help avoid damage, leading to increased end-user satisfaction.

Using a forklift with a clamp attachment enables your workers to transport more items, including heavy and uniquely shaped objects, while reducing the risk of injury. This means fewer personnel are needed to handle unwieldy items, allowing your team to focus on other essential tasks and maximizing workforce efficiency.

With a wide variety of forklift clamp types available, you can confidently choose the right size and design for your application, ensuring you complete necessary tasks effectively.

The Environmental Benefits of Hydraulic Forklift Clamps

Wood pallets have long been the standard for shipping and warehouse handling, with millions in circulation. They account for an estimated 43% of hardwood and 15% of softwood produced in the U.S. While many consider wood pallets a sustainable option—thanks to organizations like the Forest Stewardship Council—reducing their use naturally leads to less tree cutting and better forest management.

Reduced Energy Consumption

The pallet industry has debated whether wood or lightweight plastic pallets are more environmentally friendly, as numerous factors complicate the determination of a clear winner. However, one fact stands out: reducing the use of either type of pallet contributes to lower overall energy consumption.

Healthier Workplace Environment

Eliminating or reducing pallet usage by employing hydraulic lift truck attachments can also foster a healthier workplace environment. Porous wood pallets can harbor mold and insects, posing health risks. By using hydraulic clamps to move products, you can minimize physical waste and reduce the risk of accidents and illnesses associated with improper handling.

How to Control Forklift Clamp Pressure

Regardless of the clamps you use, controlling clamp pressure is essential to prevent product damage. Selecting the right pressure regulation method will add long-term value to your business. While each forklift is equipped with a fixed hydraulic pressure setting, you can easily adjust how tightly your clamp grips a specific load to ensure your goods remain intact throughout the process. This can be achieved in several ways:

- Three-Position Pressure Regulator: Mounted on the forklift, this regulator allows you to relieve pressure as needed.

- Hydraulic Force Control (HFC) System: This system automatically adjusts the clamp’s force in proportion to the weight of the load.

- Adaptive Force Control System: Utilizing preprogrammed information, this system automatically sets the clamp’s pressure, making it particularly suitable for paper roll clamp attachments.