Standard bale clamp applies efficiently and economically handlingastacking or rotating nearly any type of baled products including cotton wool, synthetic, textile bales, corrugated, newsprint, rag, hay, metal and other scrap bales in palletless operation condition. Commonly equipped in industries as paper mill material recycling, railway transportation, logistic warehouse, port, textile and related.

Features of Standard Bale Clamp

● Proven durable T-beam sliding pair, high intensity and long service life.

● High strengh T-beam alloy steel material meets all kind of operation requirements.

● Superior arm-slide bearing for extended service life.

● Inner arm with fillet design, increased the coefficient of friction Regenerative hydraulic valving for optimal arm speed.

Applications of Standard Bale Clamp

Bale clamp efficiently and economically handle nearly any type of baled products including cotton, wool, synthetic, textile bales, corrugated, newsprint, rag, hay, metal and other scrap bales. High efficiency and economy to handle in without work platform condition.

Customization Options of Standard Bale Clamp

● Custom opening ranges

● Custom arm sizes

● Custom arm ribbing

● Various mounting classes available.

● Load backrests

Standard Bale Clamp Usage Tips and Best Practices

1. Proper Installation and Inspection

Correct Attachment: Ensure that the Longhe Standard Bale Clamp is correctly attached to the forklift according to the manufacturer’s guidelines. Improper installation can lead to equipment failure or accidents.

Regular Inspection: Conduct routine inspections of the Longhe clamp for any signs of wear and tear, such as cracks, bends, or hydraulic issues. Address any problems immediately to prevent operational disruptions.

2. Operator Training

Comprehensive Training: Operators should receive thorough training on how to use the Longhe Standard Bale Clamp safely and efficiently. This includes understanding the clamp’s controls, weight limits, and maneuvering techniques.

Safety Protocols: Emphasize the importance of following safety protocols, such as wearing appropriate protective gear and adhering to operational guidelines.

3. Load Handling

Assess Load Stability: Before lifting, assess the stability of the bale. Ensure that the bale is centered and secure within the Longhe clamp to prevent shifting during transport.

Avoid Overloading: Do not exceed the Longhe clamp’s weight capacity. Overloading can damage the clamp and compromise safety.

Gentle Handling: Operate the clamp controls smoothly to avoid sudden movements that could destabilize the load. Gentle handling helps maintain the integrity of the bale and reduces the risk of damage.

4. Maintenance Practices

Regular Lubrication: Keep the moving parts of the Longhe Standard Bale Clamp well-lubricated to ensure smooth operation. Regular lubrication prevents friction and extends the lifespan of the clamp.

Hydraulic System Checks: Frequently check the hydraulic system for leaks or other issues. Proper hydraulic maintenance is crucial for the efficient functioning of the clamp.

Cleaning: Regularly clean the Longhe clamp to remove dirt, debris, and other contaminants that can affect its performance.

Maximize your operational efficiency and ensure the safety of your team with Longhe's Standard Bale Clamp. Designed for durability and precision, our clamps are the perfect solution for all your bale handling needs. Invest in Longhe today and experience unparalleled performance and reliability!

Longhe Attachment has rich experience in custom bale clamp according to various application situations. If you want to increase your production efficiency, please contact us to get a suitable bale calmp solution for your forklift of other vehicle. We are always ready for serving you with our passion and profession.

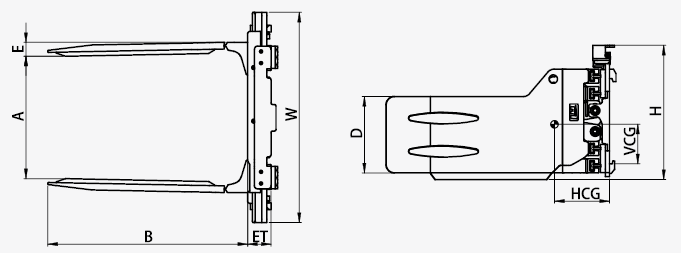

| Capacity@ Load Center | Model | Mounting Class | Opening Range | Arm Height | Arm Length | Frame Width | Arm Thickness | Overall Height | Vertical Center of Gravity | Weight | Effective Thickness | Horizontal Center of Gravity |

| (kg@mm) | A(mm) | D(mm) | B(mm) | W(mm) | E(mm) | H(mm) | VCG(mm) | (kg) | ET(mm) | HCG(mm) | ||

| 2000@500 | RBC20D-B001 | II | 450-1730 | 415 | 980 | 1040 | 75 | 707 | 193 | 411 | 130 | 282 |

| 2000@500 | RBC20D-B002/C002 | III | 450-1730 | 415 | 1180 | 1040 | 80 | 757 | 201 | 472 | 130 | 338 |

| 2000@500 | RBC20D-B007/C007 | II/III | 430-2260 | 415 | 1180 | 1040 | 80 | 707/757 | 204 | 545 | 130 | 282 |

| 2000@500 | RBC20D-B008/C008 | II/III | 430-2260 | 415 | 1400 | 1040 | 85 | 707/757 | 200 | 621 | 130 | 350 |

| 2000@500 | RBC20D-B009/C009 | II/III | 600-1890 | 415 | 980 | 1040 | 75 | 707/757 | 198 | 410 | 130 | 275 |

| 2000@500 | RBC20D-B010/C010 | II/III | 600-1890 | 415 | 1180 | 1040 | 80 | 707/757 | 192 | 472 | 130 | 337 |

| 2000@500 | RBC20D-B011/C011 | II/III | 510-2090 | 415 | 980 | 1040 | 75 | 707/757 | 203 | 450 | 130 | 250 |

| 2000@500 | RBC20D-B012/C012 | II/III | 510-2090 | 415 | 1180 | 1040 | 80 | 707/757 | 197 | 490 | 130 | 304 |

| 2000@500 | RBC20D-B013/C013 | II/III | 510-2070 | 415 | 1400 | 1040 | 85 | 707/757 | 186 | 550 | 130 | 384 |

| 2000@500 | RBC28D-C021 | III | 660-2500 | 460 | 1180 | 1040 | 80 | 773 | 227 | 729 | 150 | 298 |

| 2000@500 | RBC28D-C022 | III | 470-2310 | 460 | 1180 | 1040 | 80 | 773 | 226 | 728 | 150 | 301 |

| 2000@500 | RBC28D-C023 | III | 570-2400 | 580 | 1500 | 1040 | 85 | 773 | 242 | 811 | 150 | 417 |

| 2000@500 | RBC28D-C024 | III | 490-2330 | 460 | 750 | 1040 | 75 | 773 | 238 | 610 | 150 | 180 |

| 3200@600 | RBC28D-C001 | III | 550-1900 | 460 | 980 | 1700 | 75 | 773 | 228 | 533 | 150 | 283 |

| 3200@600 | RBC28D-C002 | III | 550-1900 | 460 | 1180 | 1540 | 80 | 773 | 220 | 585 | 150 | 358 |

Recommend Hydraulic Flow: 40L/min –120L/min

Pressure: 160 Bar

Note

1. Please contact FLT manufacture for the residual capacity of attachment

2. 2 additional hydraulic circuits required

3. Opening range refers to distance between arm tips

4. Dimension E refers to operation space required for arm

5. With sideshifting

* Further technical details are available upon request